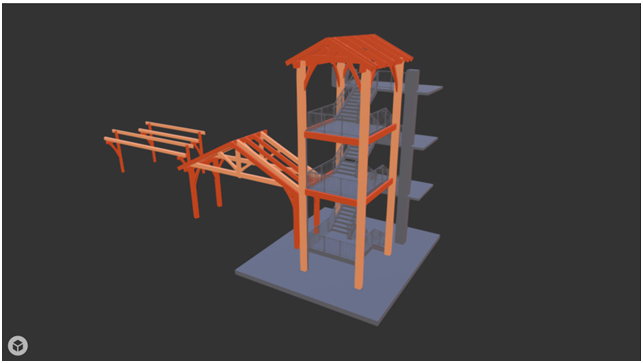

For those of you who follow my blog, you know that I am an advocate for 3d solid modeling. Not just 3d modeling but parametric modeling. Parametric modeling allows us to make changes to the model without having to start from scratch. Click here to see a short video describing the basics of parametric modeling. Bear with me as I tie this topic to our current project. We are building a timber frame tower that integrates with steel stairs. The steel stairs are being fabricated by Distinctive Welding. The general contractor is Heath Construction. Our timber frame tower needs to attach to Distinctive Welding’s stairs. The stairs will be installed first and then our timbers. It is important that our dimensions are correct and match the stair fabricator’s dimensions. One way to make sure everything has been designed to the correct dimensions is to pour over the drawings and compare our dimensions to Distinctive’s. There is another way. Distinctive Welding has created a detailed and accurate model of the stairs in 3d. We were able to import their model into our model and easily confirm that everything fits. Not only is this easier than reviewing the documents, it also gives us greater confidence that everything is going to fit.

https://skfb.ly/67JZV

Here is a view of the two models integrated. Everything in gray is Distinctive Welding’s and the colored parts are ours. It was a matter of importing the stair model and locating it in the correct position. At that point, we were able to confirm that everything fit. We were able to zoom in and take measurements from the 2 models. I call this process “a single version of the truth”. Before we brought the models together we each had our own version of what each assembly looked like. Now that they are together all of the information is in one place.

We used Sketchfab in order to allow other people to see these models without having to download a specific viewer. You can click here to see some of the other models we have uploaded.